The Problem: Why Modern Manufacturing Needs Better Data

Digital Twin Implementation in American Manufacturing: From Laser Scans to Predictive Asset Management

American manufacturers lose an estimated $50 billion each year to unplanned downtime, which is often caused by aging equipment and incomplete as-built documentation.

The solution isn’t guesswork or costly system overhauls—it’s data. By capturing facilities with precise 3D laser scanning, organizations can create digital twins that visualize real conditions, predict failures before they happen, and cut downtime by up to 50 percent while improving safety and efficiency.

As one of the leading providers of industrial laser scanning services, ARY Engineering helps manufacturers turn real-world facility conditions into actionable data that drives measurable results.

The State of American Manufacturing

Unplanned downtime costs U.S. manufacturers an estimated $50 billion every year, including lost production, missed deadlines, and mounting pressure across every level of an organization. Meanwhile, the average age of manufacturing equipment now exceeds ten years, with many plants operating machinery that has been running for decades. Maintaining these assets efficiently becomes increasingly complex without accurate documentation and continuous performance monitoring.

This is where digital twin technology comes in. Practical and scalable, it starts with a straightforward step: capturing the facility’s current reality through 3D laser scanning.

Manufacturers are trapped by outdated documentation—but modern scanning technology is breaking that cycle.

The Solution: From Scans to Digital Intelligence

Understanding Laser Scanning Benefits

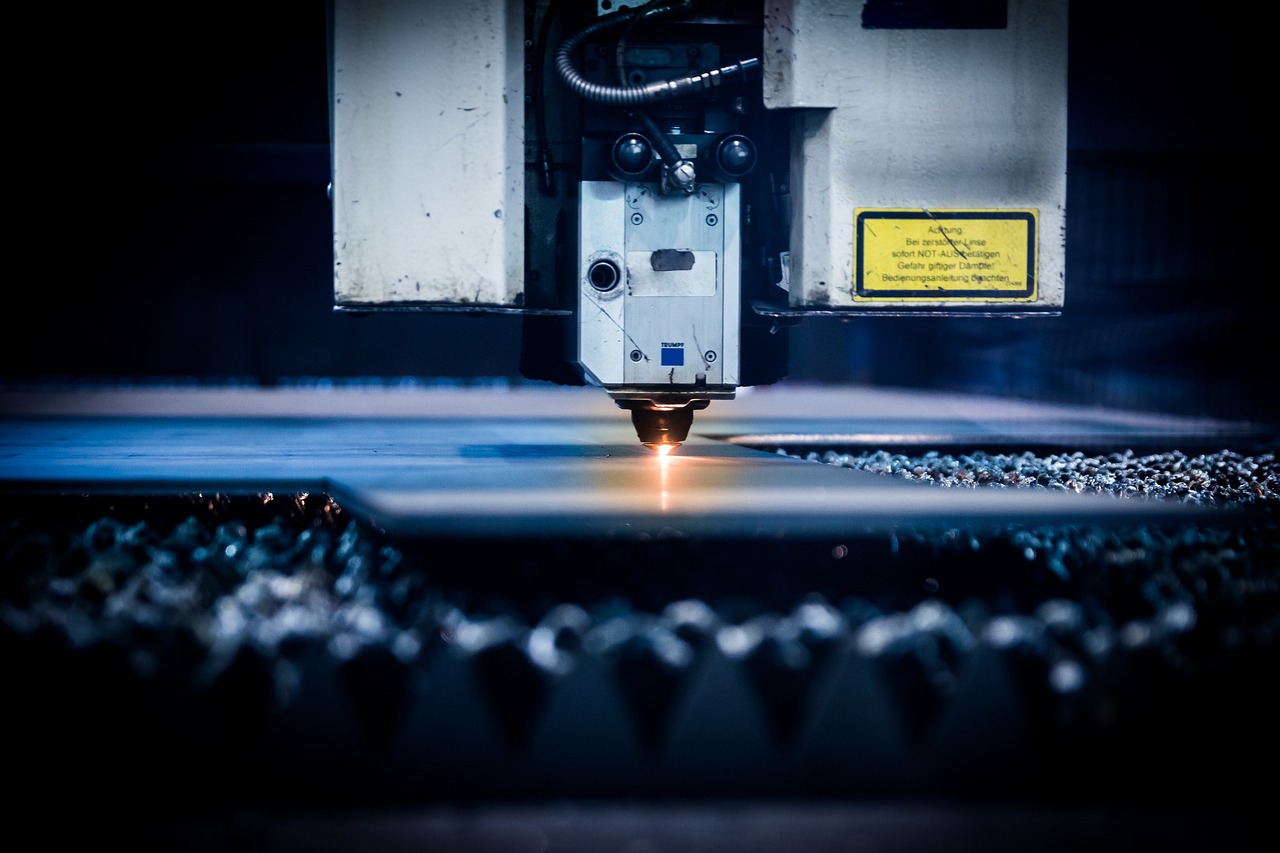

3D laser scanning captures millions of precise measurements from every surface in a facility—pipes, valves, structures, and machinery—creating a detailed point cloud that serves as an accurate digital snapshot of the real environment. These laser scanning benefits form the groundwork for accurate as-built documentation and scan-to-BIM modeling, giving engineers a dependable digital foundation for every design and retrofit project.

Unlike traditional field measurements, which rely on manual tools or outdated drawings, scanning provides millimeter-level accuracy in a fraction of the time and does not disrupt production.

Why It Matters

Every retrofit, expansion, or maintenance project depends on understanding what already exists. Even minor measurement errors can lead to misaligned equipment, unexpected clashes, or rework. Laser scanning eliminates those risks by delivering verified, high-resolution geometry that engineers can trust.

Key Advantages

- Accuracy that matters: Captures within 1–3 millimeters—10–20× more precise than manual measurement.

- Speed that saves time: A complete production area can be scanned in hours instead of weeks.

- Safety without compromise: Crews collect data from a distance, avoiding confined spaces or high-temperature zones.

- Clarity for design teams: Produces measurable, navigable 3D data that integrates directly into CAD, BIM, and digital twin systems.

From Point Clouds to Digital Twins: The Transformation Journey

The point clouds captured through 3D laser scanning aren’t just visuals—they form the foundation for a facility’s digital twin.

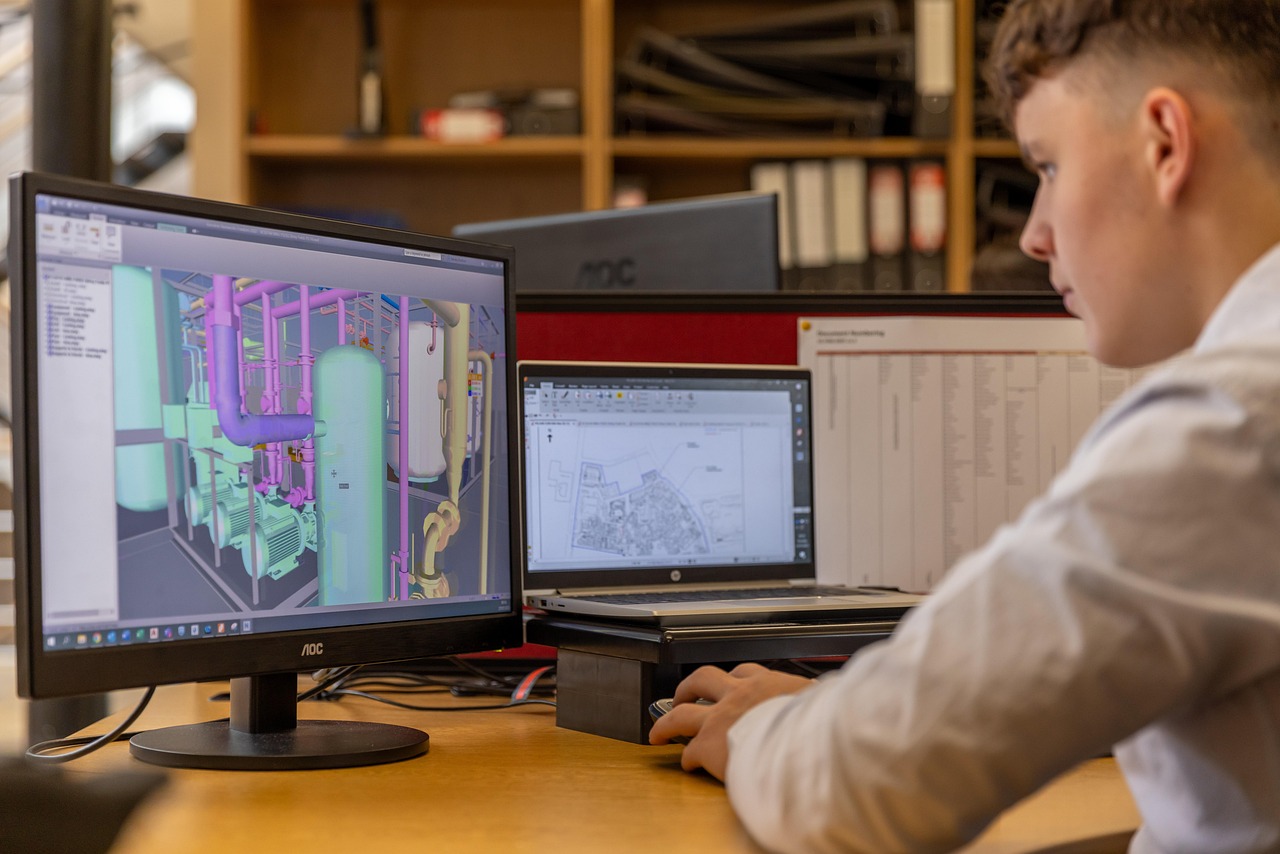

A digital twin is a dynamic, data-connected model of physical assets. It evolves alongside the real facility, providing visibility, insight, and control that traditional documentation can’t match. This process allows 3D laser scanning for manufacturing to bridge physical assets and their digital twin models, allowing data-driven decisions that improve operational reliability and reduce costly downtime.

The Four-Stage Journey

- Capture Reality – Record an accurate as-built snapshot of the facility today, revealing gaps between legacy drawings and real conditions.

- Create Intelligent 3D Models – Convert point-cloud data into intelligent BIM and CAD models that store metadata such as manufacturer, installation date, and maintenance history.

- Connect Real-Time Data—Integrate sensors and control systems so that temperature, vibration, flow, and pressure readings update the digital twin continuously.

- Enable Predictive Intelligence – With accurate geometry and live data in one environment, teams can identify issues before they occur and plan maintenance proactively.

Real-World Impact: Turning Data into Decisions

Predictive Maintenance That Delivers

Traditional preventive maintenance replaces parts on fixed schedules. A digital twin enables predictive maintenance instead—tracking performance in real time to prevent failures before they happen. Research shows predictive maintenance can cut downtime by up to 50 percent and extend equipment life by 20–40 percent, saving hundreds of thousands annually for a mid-sized manufacturer. These results demonstrate how laser scanning in manufacturing directly supports more innovative asset management, efficient maintenance planning, and more substantial long-term digital twin ROI.

Design and Retrofit Projects That Work the First Time

Retrofit projects often fail because field conditions differ from outdated drawings. With laser-scanned as-builts, engineers can test layouts virtually, detect clashes, and confirm clearances before fabrication. One aerospace manufacturer reduced design errors by 75 percent and shortened project timelines by 30 percent after adopting this workflow.

Training and Knowledge Transfer That Lasts

As experienced workers retire, decades of practical knowledge risk being lost. A digital twin preserves that expertise visually, allowing new employees to explore systems interactively and learn safely.

The ROI of Laser Scanning and Digital Twins

Implementing laser scanning and digital twin technology represents an investment—typically $50,000 to $500,000, depending on facility size and complexity. If a single downtime event costs $100,000 and a digital twin prevents even half of that loss, the technology pays for itself quickly. When combined with improved accuracy, shorter project schedules, and 10–15 percent energy savings, most manufacturers achieve full payback within 18–36 months. Beyond direct savings, facilities gain safer operations, faster decisions, and reusable data models that scale efficiently across multiple sites.

Laser scanning doesn’t just map reality—it transforms it into intelligence that pays for itself.

The Path Forward: From Insight to Action

How to Get Started

Building a digital twin doesn’t happen overnight, but it starts with a single scan. Establishing a clear roadmap for digital twin implementation ensures that every phase of laser scanning for industrial facilities delivers measurable value and aligns with operational goals.

- Start Small – Scan one critical area, such as a production line or utility corridor, to prove value quickly.

- Build on Success – Expand incrementally; each phase compounds accuracy and insight.

- Connect the Right Expertise – Coordinate between plant staff, scanning specialists, and data modelers to turn reality into usable digital assets.

- Create a Continuous Data Strategy – Maintain models with updated protocols and change tracking to remain reliable as facilities evolve.

The Future Is Already Here

Laser scanning and digital twin technologies are no longer experimental; they’re actively reshaping facilities’ operations. Manufacturers, from automotive and aerospace to food processing and pharmaceuticals, use these tools to cut costs, improve safety, and make confident, data-driven decisions. Early adopters set the benchmark for operational excellence—minimizing downtime, extending asset life, and building more innovative workplaces powered by accurate information. The question is no longer whether these technologies will become standard—it’s when every facility will adopt them and who will lead that transformation.

Moving Forward

Digital transformation in manufacturing begins with understanding the present. As digital transformation accelerates, organizations that invest early in laser scanning technology and digital twin solutions position themselves at the forefront of modern manufacturing innovation. By capturing real-world conditions through laser scanning, companies gain the foundation to build accurate digital twins, plan confidently, and transition from reactive maintenance to predictive insight.

3D scanning and digital twin adoption represent the next evolution of American manufacturing’s long innovation and continuous improvement tradition. Facilities that invest in accuracy today will lead to efficiency, sustainability, and resilience tomorrow.

The factories that thrive in the coming decades will not simply have the newest equipment—they’ll have the clearest understanding of their assets, powered by precise data and proactive decision-making. And it all starts with a laser scan.