In the dynamic environments of data centers and large production facilities, maintaining uninterrupted operations is paramount. A crucial aspect of achieving this reliability is the verification of critical subsystems—mechanical, electrical, plumbing, fire protection, and control systems. At ARY Engineering, we understand that discrepancies between original design documents and the actual as-built conditions can lead to inefficiencies, safety hazards, and costly downtime. This blog post will explore the importance of verifying critical subsystems and how a meticulous verification process can safeguard uptime and operational excellence.

Understanding Critical Subsystems

Critical subsystems are the backbone of any facility’s operations. They encompass various components, including:

- Mechanical Systems: This includes heating, ventilation, air conditioning (HVAC), chillers, pumps, and other essential machinery that ensures environmental control and operational efficiency.

- Electrical Systems: These systems power every aspect of the facility, from lighting to computing equipment. Proper documentation and verification of wiring, circuits, and breakers are vital to prevent outages and ensure a continuous power supply.

- Plumbing Systems: Often overlooked, plumbing systems play a crucial role in cooling, waste management, and fire suppression. Accurate verification is essential for maintaining operational stability.

- Fire Protection Systems: These systems are critical for safeguarding life and property. Accurate documentation ensures that fire alarms, sprinklers, and emergency exits function as intended.

- Control Systems: These systems automate processes, monitor performance, and ensure optimal operation. Accurate documentation is essential for maintaining the efficiency and reliability of these automated systems.

The Consequences of Poor Verification

Failure to accurately verify these critical subsystems can have severe repercussions for a facility. Discrepancies between design documents and the actual installations can lead to:

- Increased Downtime: Misalignments can cause unexpected failures, resulting in costly downtime and disruptions to operations. Even minor outages can lead to significant financial losses, especially in industries where uptime is critical.

- Safety Hazards: Inaccurate documentation can result in unsafe working conditions. For example, if fire protection systems are not correctly verified, operators may not be able to respond effectively in an emergency, putting lives at risk.

- Regulatory Non-Compliance: Facilities must adhere to strict safety regulations and standards. Failure to maintain accurate documentation can lead to compliance issues and potential legal ramifications.

The Verification Process: A Comprehensive Approach

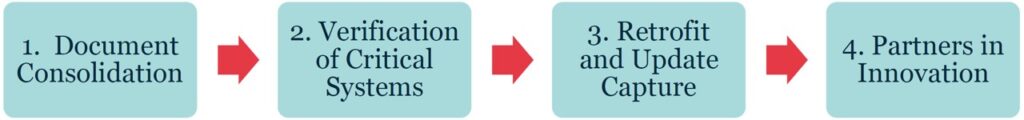

At ARY Engineering, we have developed a meticulous verification process that ensures all critical subsystems are accurately documented and aligned with real-world conditions. This process involves several key steps:

1. On-Site Inspections

The verification process begins with our expert team conducting thorough on-site inspections of the facility. Armed with the consolidated master CAD/BIM file, we systematically compare the documented design against the actual installed conditions. This meticulous on-site verification ensures that every component, from mechanical systems to electrical circuits, is accurately represented in the documentation.

For facility operators, this step is crucial. It means that the master CAD/BIM file they rely on reflects the true state of the facility, eliminating guesswork or assumptions. Whether identifying the exact placement of plumbing lines or verifying the integration of fire protection systems, our goal is to provide a precise and reliable reference that operators can trust in both routine and emergency situations.

2. Mechanical Systems Verification

Mechanical systems form the backbone of any facility, encompassing HVAC units, chillers, pumps, and more. Our verification process involves a detailed assessment of these systems, ensuring that their documented layouts, capacities, and operational parameters match the actual installations.

This verification is critical for optimizing climate control, preventing equipment overheating, and ensuring that the facility’s environment meets the stringent requirements of data processing or industrial production. Moreover, accurate mechanical system documentation enables quick diagnosis and correction of any issues that may arise, helping operators avoid disruptions that could compromise uptime.

3. Electrical Systems Verification

Electrical systems are the lifeblood of any data center or factory. Ensuring that every wire, circuit, and breaker is correctly documented and verified is essential to preventing outages and maintaining a continuous power supply. Our team conducts thorough inspections of the facility’s electrical infrastructure, cross-referencing the master CAD/BIM file with the actual installations.

This process confirms the accuracy of electrical schematics and helps identify undocumented modifications or upgrades made over time. By updating the master CAD/BIM file with verified information, we empower operators to manage the electrical system with confidence, reducing the risk of overloads, shorts, or unexpected failures.

4. Plumbing Systems Verification

Plumbing systems, while often less visible, are critical for maintaining facility operations, particularly in cooling systems, waste management, and fire suppression. Our verification process extends to these essential systems, ensuring that piping layouts, flow rates, and pressure settings are accurately documented.

For operators, this verified information is vital for maintaining the integrity and efficiency of plumbing systems, especially in environments where precise temperature control and water management are crucial. Accurate plumbing documentation supports operational stability and uptime, mitigating the risk of failures that can lead to downtime.

5. Fire Protection Systems Verification

Fire protection systems are a critical safeguard in any facility, designed to detect and suppress fires before they can cause significant damage. Our verification process includes a thorough review of fire alarms, sprinklers, suppression agents, and emergency exits, ensuring that the master CAD/BIM file accurately reflects their locations and operational status.

This verified documentation is essential for daily operations and compliance with safety regulations and emergency response planning. In an emergency, operators and first responders can rely on the accuracy of the documentation to quickly locate and activate fire protection systems, minimizing potential harm to life and property.

6. Controls Systems Verification

In today’s data centers and industrial facilities, control systems are the nerve centers that automate processes, monitor performance, and ensure optimal operation. Our verification extends to these critical systems, where we assess the accuracy of control panel layouts, sensor placements, and system integrations documented in the master CAD/BIM file.

Accurate documentation of control systems is essential for maintaining uptime, as it allows operators to quickly identify and troubleshoot issues, adjust settings, and ensure that all automated processes are functioning as intended. By verifying these systems, we help operators maintain a high level of control over their facility, reducing the likelihood of unforeseen disruptions.

Want to know how As-Built verification fits into an improved Uptime Strategy, ensuring data centers and factories operate safely, efficiently, and with minimal interruptions? Download the FREE whitepaper today!

Delivering Confidence Through Verified Documentation

At ARY Engineering, the verification of critical subsystems is not just a procedural step—it’s a commitment to delivering confidence and reliability to facility operators. By ensuring that every mechanical, electrical, plumbing, fire protection, and controls system is accurately documented and verified against real-world conditions, we provide operators with the tools they need to maintain uptime and operational excellence.

This rigorous verification process enhances safety, supports proactive maintenance, and enables rapid response in emergencies. It is essential for minimizing downtime and protecting the reputation of the businesses we serve. With verified documentation, operators can focus on what they do best: keeping their facilities running smoothly, efficiently, and safely.

Conclusion: Prioritizing Verification for Success

In conclusion, verifying critical subsystems is a vital component of maintaining operational integrity in data centers and large production facilities. At ARY Engineering, our comprehensive verification process ensures that all systems are accurately documented, enabling operators to work with confidence and reducing risks associated with miscommunication and outdated information.

By prioritizing the verification of critical subsystems, facilities can significantly enhance their operational efficiency, safety, and compliance. As you look toward the future, consider how investing in a robust verification process can drive long-term success and resilience in your operations.

Are you ready to ensure the reliability of your facility’s critical subsystems? Contact ARY Engineering today to learn more about our verification services and how we can help you achieve operational excellence. Let us be your trusted partner in safeguarding uptime and enhancing the integrity of your operations!