What do manufacturers care about?

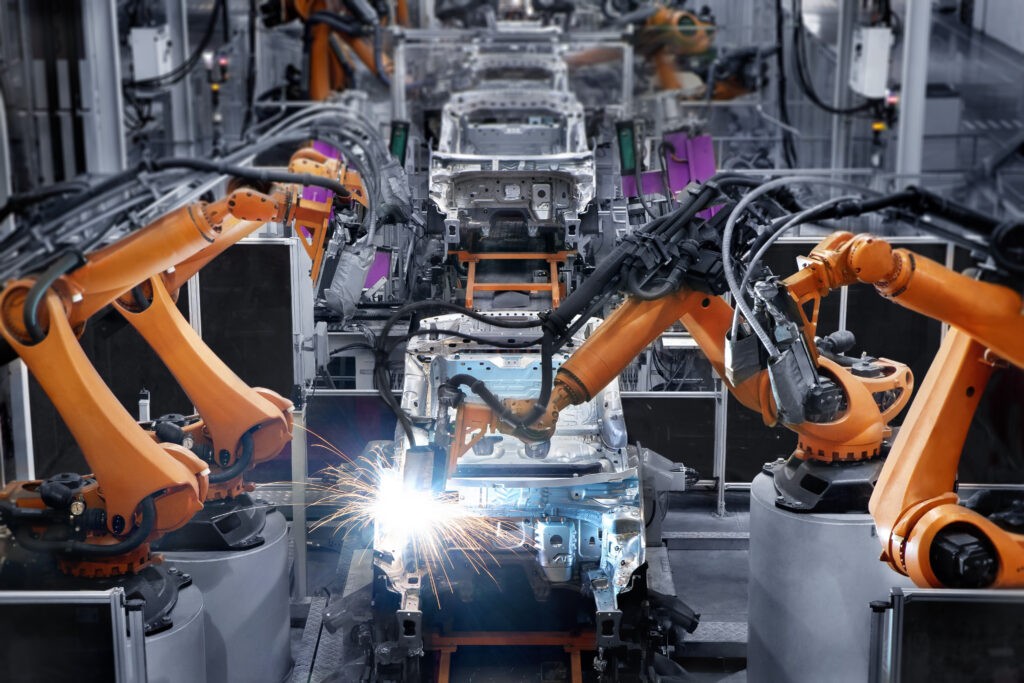

Short answer: Throughput

Most manufacturing facility’s’ revenue is directly linked to their throughput.

Throughput is the quantity of product a company can produce and deliver within a specific timeframe.

Whether producing vehicles, raw metals, or furniture, the primary goal of such manufacturing facilities is to increase throughput, which can be done by increasing facility capacity, or decreasing the throughput time.

Throughput time is the actual amount of time required for a product to pass through a manufacturing process, converting from raw materials into finished goods. This includes the time of processing of raw materials into components or sub-assemblies.

Operating a manufacturing facility, much less drastically improving throughput, is challenging, with constraints ranging from talent availability to supply chain chokepoints. Below, we explore some of the services that ARY Engineering offers, and how they enable you to improve your throughput.

As-Builts for Manufacturing

An as-built is a set of drawings that document how something exists in its current state, as opposed to the plans that were originally used for the design.

ARY’s design team splits as-builts into 2 categories: Area As-Built (AAB) and Equipment As-Built (IAB).

Area As-Built (AAB)

The documentation of a specific area, encompassing utilities, equipment footprints, and architectural, mechanical, electrical, civil, and structural disciplines.

Typical facility as-built deliverables include:

- Plan sets of the area chosen

- Electrical and mechanical equipment schedules

- Diagrams, including P&IDs, one-lines, and risers

Equipment As-Built (EAB) – Reverse Engineering

The documentation of a specific tool or piece of equipment, often with the purpose of creating a replacement, whether identical in form or in function.

Typical equipment as-built deliverables include:

- 3D models, often generated with 3D scans

- Shop drawings

- A foundation for creating a novel design of a replacement

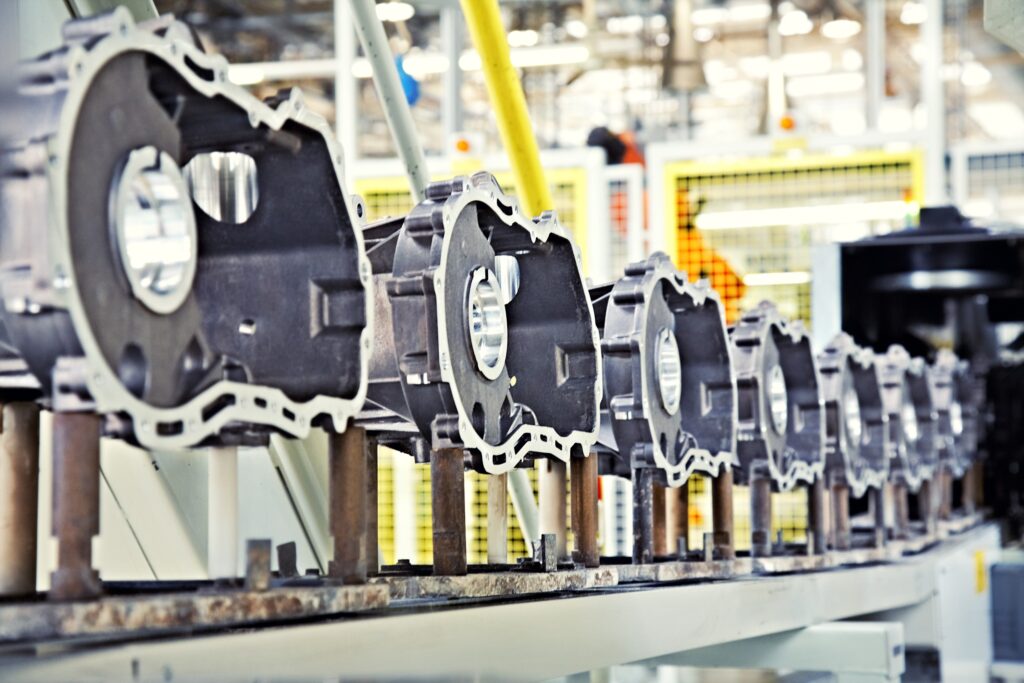

Process Design – Lean Manufacturing

The path raw goods take through a manufacturing facility as they transform into the final deliverable is often a complex and interlinked set of processes . However, there are often bottlenecks, where a specific step of the process has limited capacity and reduces the capacity of the entire production chain.

A process bottleneck is a work stage that gets more work requests than it can process at its maximum throughput capacity.

Bottlenecks create…

- Negative impact on product flow

- Under-utilization of most resources due to over-utilization of a few

- False ceiling for maximum theoretical production figures

- Decreased throughput

ARY’s solutions deliver…

- Increase in resource capacity

- Elimination of non-value operations

- Improved flow of operations

- Re-allocation of resources

- Novel process design, where necessary

- Increased throughput

Machine Design For Manufacturing and Assembly (DFMA)

Although the theoretical design and simulation of new products is critical in the design process, the final “shop drawings” is where the rubber really hits the road. “Shop drawings” are known as the prints produced by the designer that are directly used to manufacture a specific product. However, not all shop drawings are made equal.

Design for Manufacturing and Assembly (DFMA) is the process of designing parts, components, or products for ease of manufacturing with an end goal of making a better, more consistent product at a lower cost.

ARY’s proprietary DFMA process results in:

- Cost reductions per part

- Elimination of unnecessary parts

- Creation of modular designs

- Improved product consistency

- Smoother manufacturing process

- Reduced resource waste

- Ability to scale production without compromise

Power Studies and Redundancy Engineering

From a balance sheet perspective, a manufacturing facility is a physical asset that turns raw goods and electricity into profit. As a result, unexpected power losses can be extremely detrimental, whether due to a grid failure or an internal miscalculation.

To prevent costly losses, ARY’s power engineering team can implement a coordination study, including :

- Arc Flash Analysis

- Short Circuit Study

- Load Calculations

- Motor Starting Analysis

- Voltage Drop Analysis

- Overcurrent Setting Review